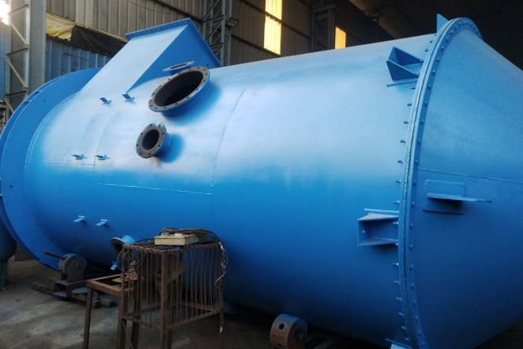

Corrosion Resistant Rubber Lining

Corrosion resistant Linings are used to provide protection to process equipment and structures made of Carbon Steel, concrete or other subs tracts, from effects of corrosion. Process equipment made of Carbon steel and protected with appropriate rubber linings is usually more economical than the same equipment fabricated of an alloy or more corrosion resistant metal.

Latest Polymers Rubber has from inception been involved in the rubber lining of Equipment's, Pipes and Fittings and other components in Caustic and Chlor Alkali projects, Phosphoric Acid and Fertilizer Industries , Water Treatment Plant, Effluent Treatment Plant and Desalination Plants, Flue Gas Desulphurisation Plants and many more.

Abrasion Resistant Rubber Lining

Abrasion Resistant Rubber lining are widely used in the Ore handling & Mineral Processing industry, for transportation of Slurry/Minerals. Latest Polymers has special compounds for this type of application which are proven in the field, from the year 1981. Abrasion resistant lining sheets are normally manufactured in the thickness range of 6mm-10mm, single ply made out of Soft Natural Rubber.